Multiple-Degree of Freedom Cavity Resonator System

Project MCAP-CR

日本語ページはこちら

|

Advanced Loudspeaker Application Development Project Multiple-Degree of Freedom Cavity Resonator System Project MCAP-CR 日本語ページはこちら |

|

| MCAP-CR is typical application of Multiple-Degree of Freedom Cavity Resonator.

You will find more details in Technical Documents. There are a number of applications of standard MCAP-CR loudspeakeer system. We will see standard MCAP-CR applications, CBS-CR, and AICC-CR applications in this section. QNDR is as well interesting. See below: |

|

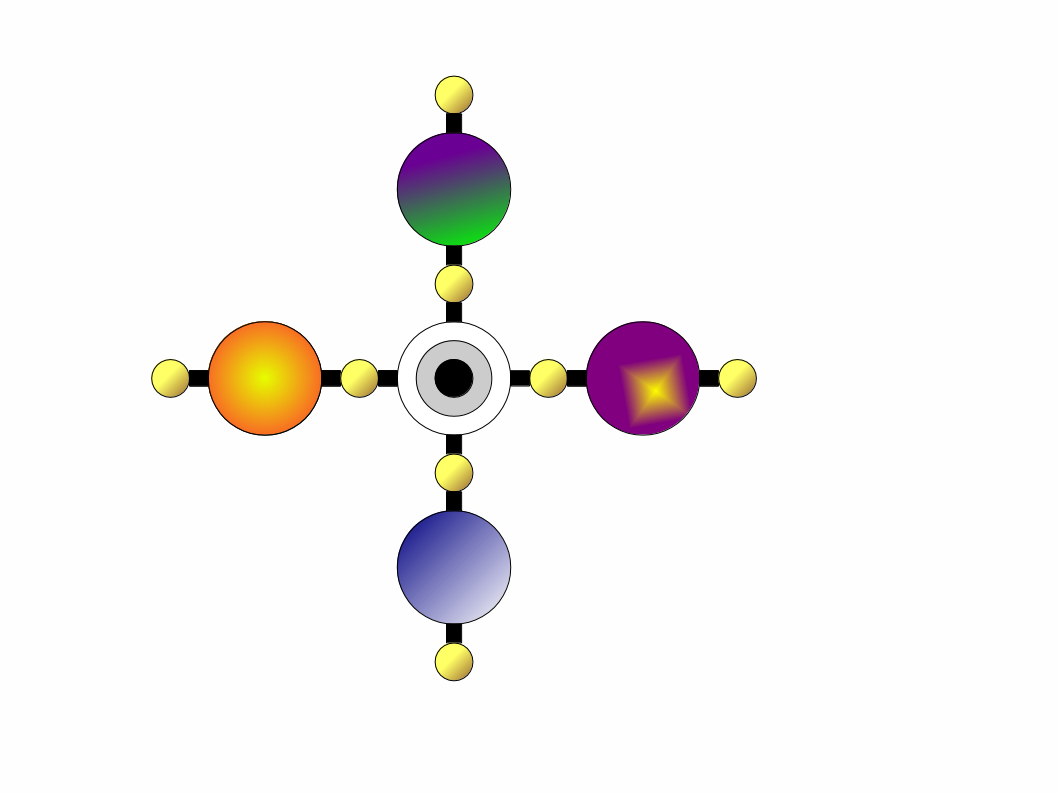

Fig.2 Standard MCAP-CR

|

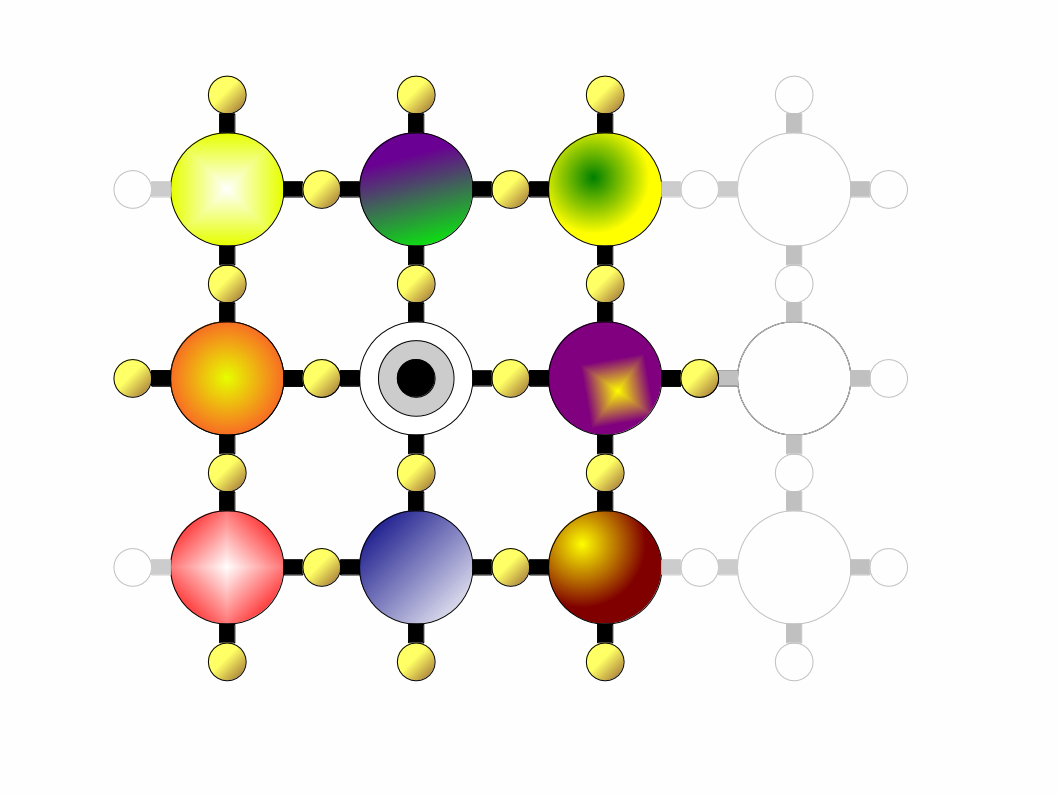

Fig.3 Idea of CBS-CR

|

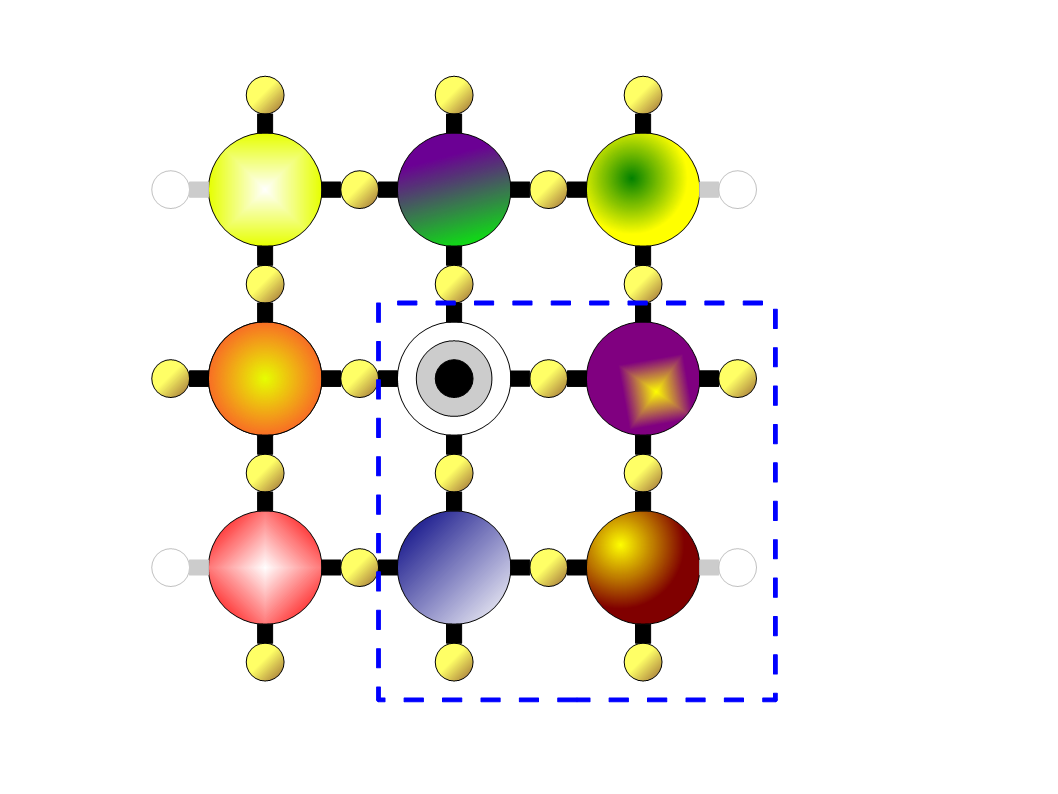

Fig.4 Simplified CBS-CR

|

| This is standard MCAP-CR with 4 subchambers. |

The is original concept of CBS-CR.

There are 4 directly connected subchambers and 4 indirectly connected subchambers.

All the chambers can be allingned in single plane.

CBS-CR may be extended as gray part. |

Because left one is too complex,

only four chambers are extracted, then simplified. We tried this simplified structure compared with MCAP & AICC-CR. |

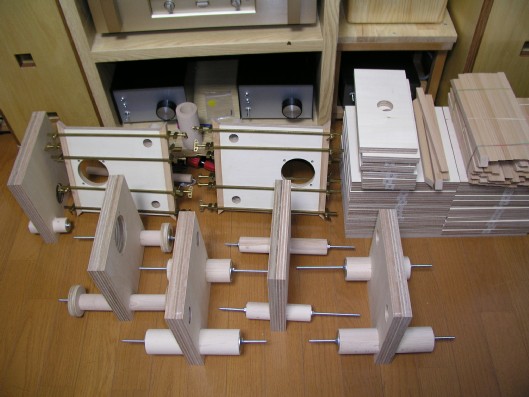

Fig.5 Minimum CBS-CR Model

|

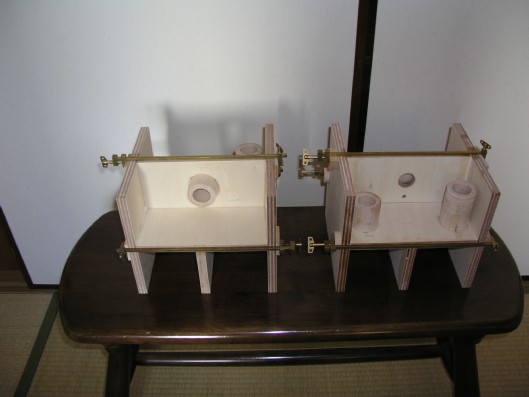

Let us see structure of the simplest CBS-CR in the left hand side. We may allign all the chambers in a single plane, but actually made one has 3D alligment, in order to compare with MCAP & AICC-CR. As seen in the picture in the top of this page, all the applications are made as cute cubic style. |

|

In order to maximize efficiency of plate cutting plan, materials of

side edges were made separately. 15mm x 15mm squared log was used for

side edge and pre-cut. Used saw is called "precision meiter saw". This is very practical to cut small-sized log precisely. Squared log was set and clamped as in the left picture and saw was reciplocated by hand, then acurate 45 degree was given as in the picture. The side edge materials and wood pipe ducts were pre-cut as in the below left picture. Some materials had to be separated to two pieces, in order to save square log materials. Pre-cutting these materials are very important to assemble accurately. |

|

Some wood pipe ducts were combined and glued in order to save wood pipe materials. Wood pipes are very expensive, so that ducts may be made by paper or PVC pipes may be substituted.  |

|

Component materials are combined and glued, then left for a few days. One day is minimum term to secure strength of gluing. This is the most patient time for loudspeaker builders. |

|

Pre-assembly continues... |

|

Finally, assembly complete. Then ground down all the edges and corners.  |

|

After finishing, finally MCAP-CR family became complete. All the systems MCAP/AICC/CBS-CR look same. It was really ideal for comparison. All the systems were compared with my friend, Mr. Matsu. He was surprized at the exterior of these systems. They looked same for him. He began listening without knowing deferences of these systems. His impression was diference among these systems were very small. Changing music sources and listening intensively then difference was detected. He told me AICC-CR gave the best sound field presence. It regenerated clear drum attackss, according to him. |

|

Lowest end frequency was around 37Hz, so that low frequency range sounded enough using these systems. After that, all the systems were demonstrated at 1st conference of "Research Institute of Loudspeaker and Related Technologies", most people graded that CBS-CR was the best favorite. My impression is that standard MCAP-CR is the best favorite. Standard MCAP-CR demonstrates most natural sound for me. There is no conclusion which is the best, but I guess order changes every time. All the system became proven. Click "SEND MESSAGE" in the top left menu. |